Chrome Bars

Mirro-Krome 60®

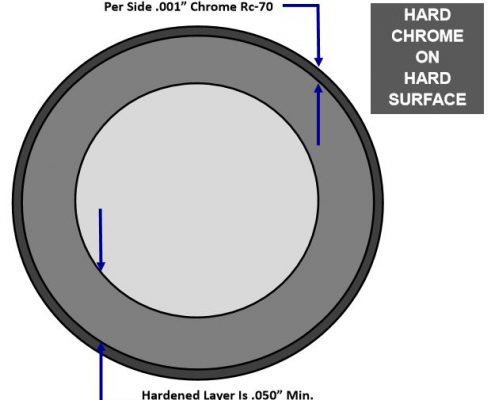

(I.H.C.P.) Induction Hardened, Chrome Plated Shaft

Mirro-Krome 60 is a well-balanced electric furnace steel that has been stress relieved, turned, ground and polished. It is then induction hardened and electro chromium plated. This shafting material is engineered to take a high degree of sliding and rotating abrasion. The induction hardening process provides resistance to side impact and increases wear resistance. Surface hardness is Rockwell “C” 50 minimum and finish is 12/15 RMS. Call or email us for a quote.

Rigid quality standards ensure excellent internal soundness and uniformity of chemistry. Surface condition and wearability are verified. An excellent choice for hydraulic and pneumatic applications.

Spacing

Features

Induction Hardened

Chrome Plated

Abrasion Resistance

Corrosion Resistance

Polished Finish

Fatigue Resistance

.

Typical Properties*

| Case Hardness | Rc “50” min |

| Depth of Plating | Per Side .001″* |

| Yield | Approx. 100,000 P.S.I. |

| Elongation in 2″ | 10% |

| Reduction of Area | 38% |

| Finish | 12/15 RMS |

*Based on 1/2″ test piece

.

Available Sizes

5/8″

3/4″

7/8″

1″

1-1/8″

1-1/4″

1-3/8″

1-1/2″

1-3/4″

2″

2-1/4″

2-1/2″

2-3/4″

3″

3-1/4″

3-1/2″

4″

4-1/4″

4-1/2″

.

Lengths

10/12 Ft, 20/24 Ft. R/L and Custom Cuts

.

Typical Diameter Tolerances

| Up to 3” Round | (+.000”/-.002”) |

| Over 3” to 4” Round | (+.000”/-.003”) |

| Over 4” Round | (+.000”/-.004”) |

| Up to 38MM Round | (+.000”/-.001”) |

| Over 38MM to 60MM Round | (+.000”/-.002”) |

Applications

- Cam Shafts

- Dowel Pins

- Guide Pins

- Piston Rods

- Hydraulics Rams

Boxing is recommended to protect during shipment.

Spacing

*Certain smaller sizes may have modified analysis and (.0005″) chrome thickness per side.