High Strength Steels

Kromite® Threaded Bar

Heat Treated, Roll Threaded Rod

Kromite Threaded Bar is made of heat treated, high strength, alloy material. It is the ideal threaded rod to be used when strength and toughness are key requirements.

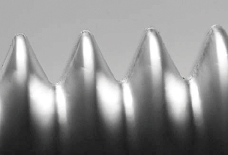

Kromite Threaded Bars are manufactured with a rolled thread vs. a cut thread. This product is virtually free of tears, chatter marks and tool marks that are commonly associated with cut threads. Such imperfections in cut threads are points of stress that cause fatigue failure in service. Consider Kromite Bar for your maintenance needs.

Material conforms to specifications for: ASTM A193, Grade B7. Call or email us for a quote.

Features

Heat Treated

High Strength – Alloy Material

Rolled Threads vs Cut Threads

Excellent Toughness

Creep Resistant

Consistent Grain Structure

High Degree of Accuracy

Precision Class 2A & 2G Fit

Agency Concurrence

ASTM A193, Grade B7

.

Lengths

10/12 Ft. R/L and Custom Cuts

.

Typical Properties*

| Hardness | 321 BHN |

| Tensile | 155,000 P.S.I. |

| Yield | 135,000 P.S.I. |

| Grain Size | 7 |

| Elongation in 2″ | 19% |

| Reduction of Area | 53% |

*Based on 1/2″ test piece

.

Available Sizes

5/16″ (18)

3/8″ (16)

7/16″ (14)

1/2″ (13)

9/16″ (12)

5/8″ (11)

3/4″ (10)

7/8″ (9)

1″ (8)

1-1/8″ (7)

1-1/4″ (7)

1-3/8″ (6)

1-1/2″ (6)

1-3/4″ (5)

2″ (4-1/2″)

2-1/4″ (4-1/2)

2-1/2″ (4)

.

Grain structure is maintained in continuous unbroken lines, increasing tensile and shear strength. As opposed to a commercial “cut” threaded bar where sharp cuts and gouges weaken the threads and can serve as stress risers.

(equivalent to Sheffield™ Stud Stock)

For a downloadable PDF flyer click on the button below.

The strength of our threaded bar is in the rolling process. Thread rolling deforms the blank material as it is forced along the contour of the die. The worked material is strain hardened, resulting in a product stronger and harder with minimal risk of fatigue relative to cut threads.

.