Redi-Rail®

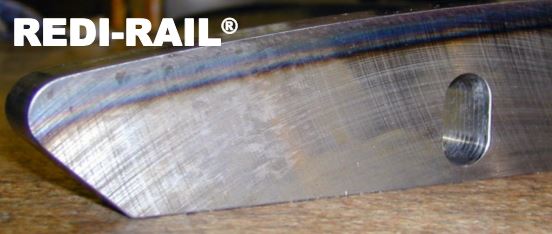

Redi-Rail® Custom Flame Hardened, Precision Cold Finish, Wear Rail

Redi-Rail® is a custom manufactured, precision “wear rail” component. Hardness range from 38/42 or 55/62 Rockwell “C” depending upon the application. It is suited to handle many applications including: transfer rails, conveyor guide rails, machine ways, beef rails, heavy-duty tracks and various OEM parts. Its wear resistant properties far exceed that of “cold roll” steels even after further heat treatment is applied.

Redi-Rail® is engineered to outlast C1045, C1060, 4140, and 6150 in similar applications; is offered with undersized Cold Drawn tolerances.

Redi-Rail®, a complete turn-key approach for precision “wear rail” requirements.

When custom rails are manufactured, there are inherent risks when utilizing multiple sources (machine shops, heat-treating firms, machine straightening facilities) to produce a final product. Associated Steel Corporation provides a one-stop solution. Call or email us for a quote.

Key Features

Straightness Furnished – straightened after thermal treatment to .035″ per 10 feet (restrictions apply).

Twist and Bow – custom flattened and de-twisted to your exact requirements upon the application.

Depth of Case – as required up to .125″

Hardness of Case – Material may be hardened from 55/62 Rockwell “C” or tempered down to 38/42 depending upon your application.

.

Available Inventory

- Flats (1/4″ x 1″ up to 2″ x 6″)

- Squares (3/8″ up to 4″)

- Metric Size Options

- Beef Rail Stock (call for specific details)